LED indicators are designed to provide a clear status signal in a wide range of applications and give clear visibility in both low-light and high-glare conditions. These components provide an integral part of control panels in industrial manufacturing, with their role becoming ever more crucial as processes improve and automation is adopted more widely.

In this blog we’re investigating the important role that illuminated indicators play in industrial environments in order to keep everything running as smoothly and safely as possible.

Safety

One of the key functions of LED indicators in industrial settings is to effectively communicate safety-related information. Reducing risks to operators, equipment and products is becoming ever more important as the implementation of high-speed operations and intelligent controls gains popularity.

LED indicators offer explicit signalling with high visibility to alert users to any fault within a system, so that accidents can be avoided and the problem can be rectified as soon as possible to reduce the impact on production. This can be boosted further by an audible warning system, such as a buzzer.

With a low voltage and minimal heat generation, LED indicators are also a safer option than their alternatives, as they minimise the risk of fire or other electrical hazards.

Additionally, if an incident does occur and you find that you have lost power in a certain area, an LED indicator can help you to identify that the emergency lighting or power systems are operational.

System Status

In addition to increasing safety around industrial environments and machinery, LED illuminated indicators can be used to easily signal the status of a system to operators, as well as for diagnosis of any issues.

Single or dual-colour indicators (these may also be referred to as pilot lights) can be used to signal whether a machine is on or off. But if you have a more complex process with additional stages, multiple indicators or multi-coloured indicators can be used to denote each individual stage of the process.

User Feedback

A key benefit of illuminated indicators is that they can be used to enhance the feedback and interaction between a machine and its user. One example of this is that an LED indicator may light up to indicate that a command has been received or that a certain process or system has been activated.

Indicators may also be used to feed back the progress of a task. For example, a series of indicators in a row could be used to represent how far along the task is, with each one lighting up in turn. Similarly, a traffic light system with red, amber and green LEDs can be used as it progresses.

Our LED Indicators

Our metal illuminated indicators are a popular choice for a wide range of applications as they are designed to be durable and robust. We offer these indicators in a range of sizes from 8mm to 30mm, with IP rated and RGB illuminated options available.

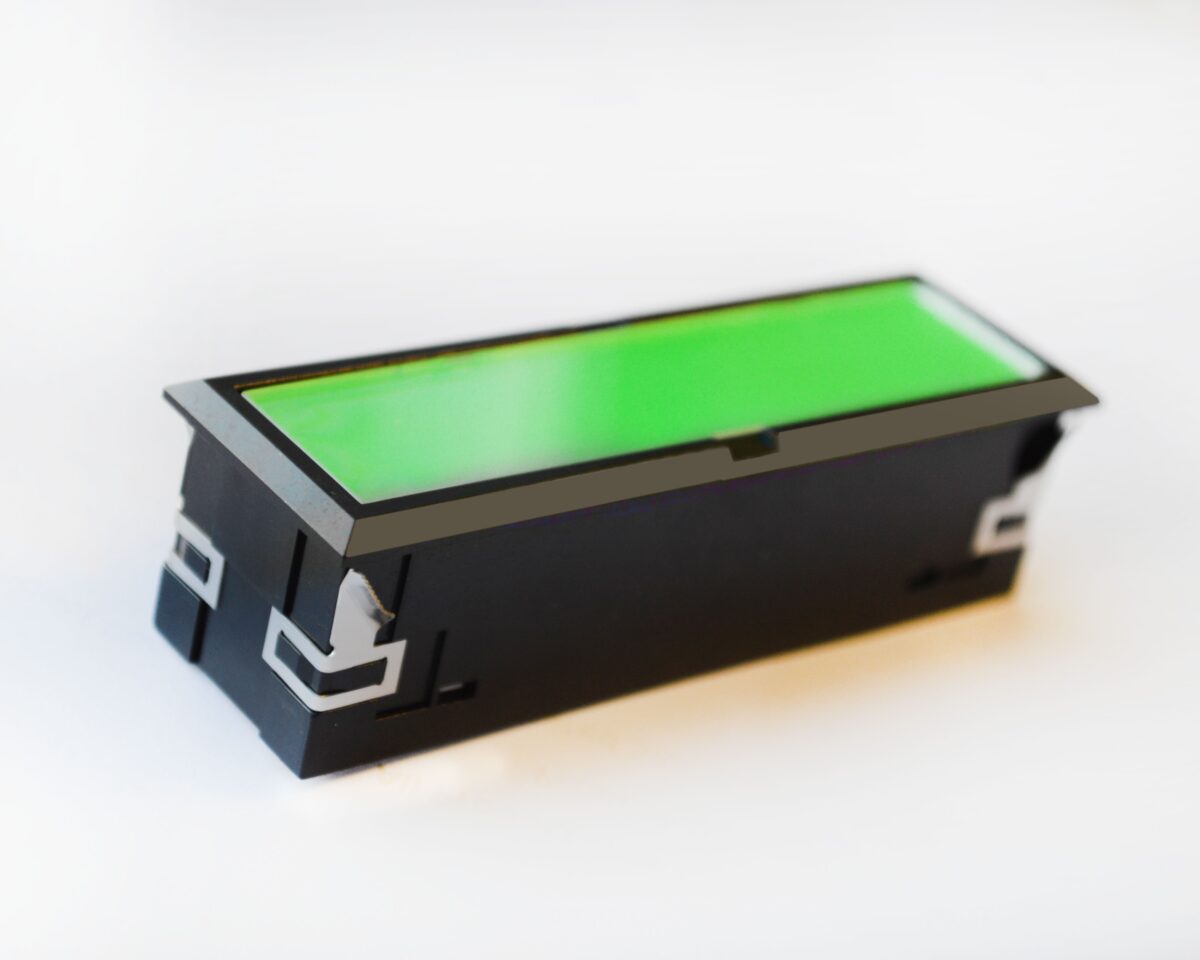

Our plastic LED indicators benefit from full-face LED illumination, and are available in more shapes and styles than our metal series. These indicators are available with round, square or rectangular caps, and we also supply IP rated and ultrabright options.

The key, standout feature of our panel indicators is their modular design that allows you to fit multiple indicators together on a panel; offering greater flexibility. You can choose full-face or split-face illumination for our panel indicators.

LED Indicator Colours

The colour, or colours, of the LED indicators that you choose will often depend on what you need to use them for, as different colours denote different statuses or warnings. The most common indicators colours and their meanings are as follows:

Red

A warning of a dangerous situation that requires immediate attention, such as power surges or failures, or an abnormal rise in temperature, etc. These can be used in conjunction with an emergency stop switch to immediately shut down operations when an incident occurs.

Yellow

A warning of an abnormality in the system (e.g. overheating) that may lead to a dangerous incident if not monitored.

Green

Most commonly used to indicate that the system or machinery is running normally and correctly, with no risk of an incident. In dual or three-colour LED indicators, green is typically the colour that signifies that the indicator is in standby mode.

Blue

Used to signal a certain status of the machine, or to alert the operator that an action is required, such as resetting it to start a new cycle.

White

The most versatile colour of indicator, but is commonly used to show status (e.g. on/off), or to better fit with the aesthetics of the device.

Other Applications of LED Indicators

Robotics – Increases the safety and user experience of robotic systems, with task indication, navigation and diagnostic functionalities.

Medical – Allowing medical professionals to assess the status of critical devices in an instant.

Transportation – Enhances the safety of various vehicles and transportation infrastructure.

Energy – Particularly important to signal changes in system status when controlling more volatile energy sources.

Aerospace – Critical for system functionality, safety, efficiency, and pilot awareness.

Summary

LED indicators are the go-to choice for monitoring the safety and system status of industrial machinery and processes; with a long lifespan, low power consumption and high durability. Plus, you can increase the overall efficiency of production in industrial environments by implementing illuminated indicators that can easily feedback information to the users.

Whether you are in need of metal, plastic or panel LED indicators, we offer a wide range of styles to suit your needs. Speak to our Sales Engineers today to find out more.

Interested in our products? Speak to us today!

How to place an order?

We operate Monday – Thursday (8 am – 5 pm) and Fridays (8 am – 4.30 pm)

Call us on +44 (0) 1234 213600 to speak to our Sales Engineers or e-mail us

on [email protected] alternatively, leave us a message using our online contact form.

View our full product range here | Download our recent product catalogue

Switch on.

Sign up to our mailing list for the latest news, product notification and so much more!

Just one click away…